The new paper machine Andritz AG (Austria) is being installed at the new plant of Arkhbum Tissue Group, the affiliated company of Arkhangelsk PPM, JSC (the shareholder is Pulp Mill Holding) in Kaluga Region.

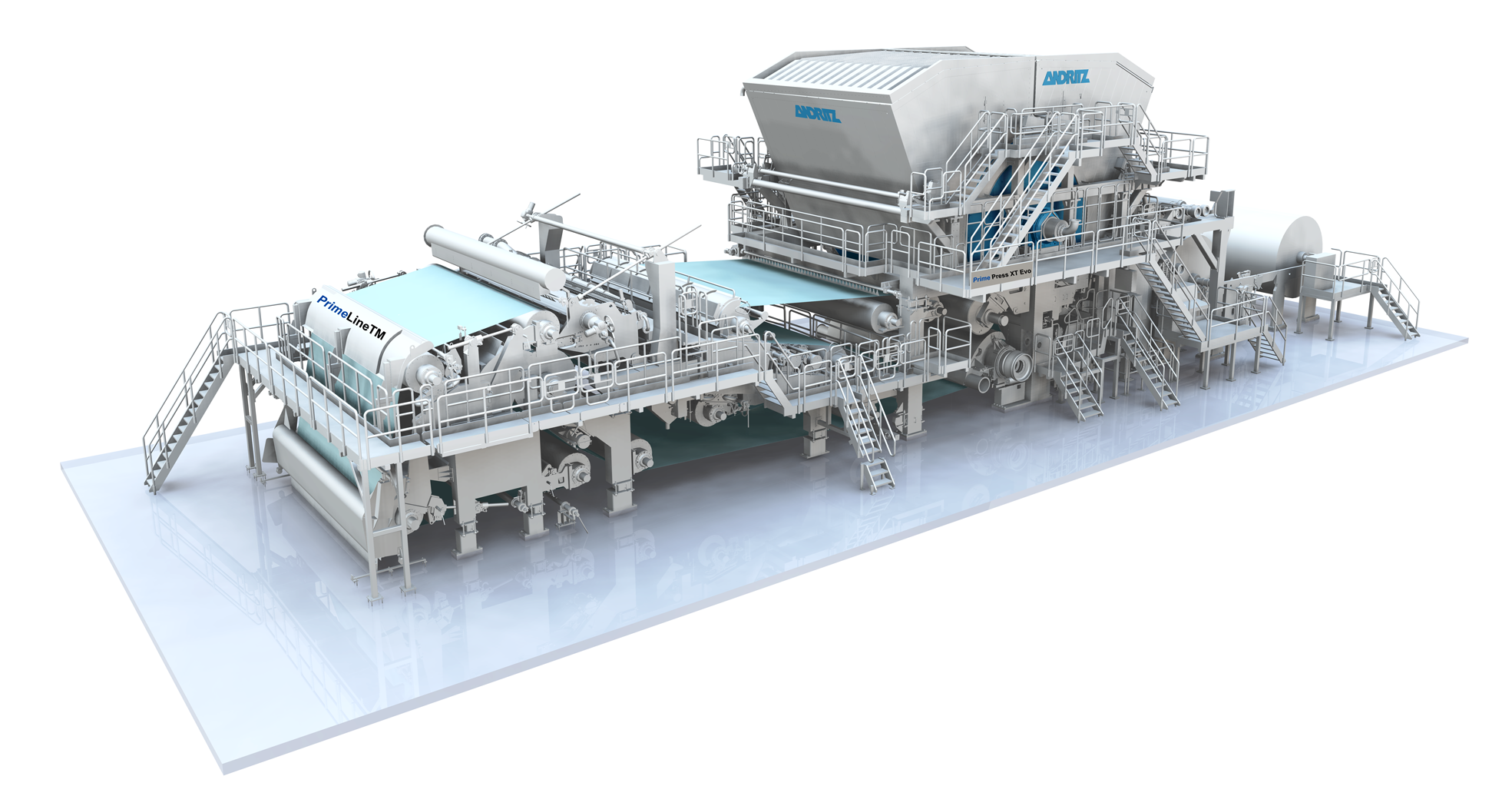

The equipment was custom-built for Arkhbum Tissue Group. The new PM is notable for its highest level of safety in operation, new engineering solutions in the process of stock preparation and in the system of web dewatering and drying.

The cost of the new paper machine is over €20 million. The cost of the winder is over €3 million.

The main parameters of the PM are the following: working width – 6.1 m, length – 35 m, height – 10 m, working speed – 2000 m/min, trimmed width – 5.6 m, reel diameter – 3 m.

The machine will produce 70 thousand tons of tissue per year.

All the installation works are carried out by the personnel of LS-Group (Saint Petersburg) under the technical supervision of Andritz AG.

Start-up of the new PM is scheduled for September 2019.

According to Petr Podelenyuk, Head of Operations and Maintenance, in parallel with the installation of the PM, the construction of the steam boiler house is carried out, since Andritz process technology provides use of saturated steam as a source of heat energy. The plant has been already supplied with two steam boilers manufactured by Viessman (Germany) with the capacity of 10 tons of steam per hour each.

Along with the installation of the PM, construction of the treatment facilities is in progress, the equipment manufactured by Flootech (Finland) is already being prepared for the installation.

As Vladimir Krupchak, the member of the Board of Directors of APPM, said earlier, after the commissioning of its own paper machine, Arkhbum Tissue Group is planning to consider the possibility of launching the second after Soffione brand.

Currently, the company is successfully selling its products throughout European Russia: the company has concluded contracts with large federal chains.